Table of Contents

Procurement performance metrics, also known as procurement KPIs or key performance indicators, help organizations measure efficiency, compliance, and cost savings across the procurement cycle. Supply chains worldwide experienced unprecedented interruptions as businesses sent employees home amid COVID-19 precautions during the global pandemic. Traditional in-person B2B sales changed suddenly, and the rapid transition to remote work made paper and email-based workflows unreliable and unsustainable.

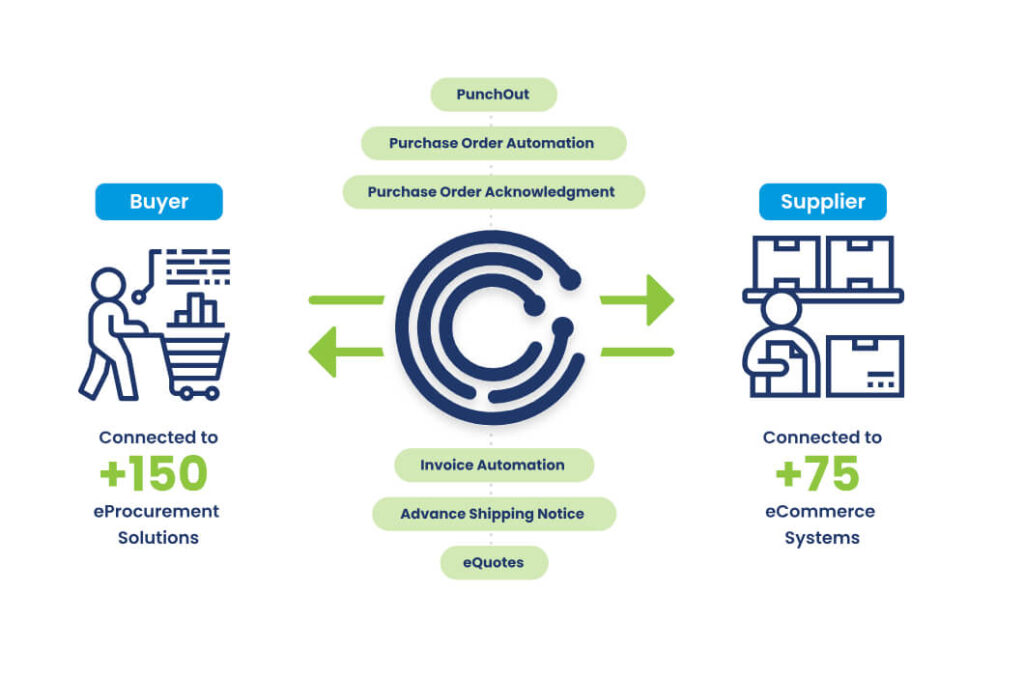

Procurement departments stepped up to meet the challenge, which often meant implementing more digitally focused processes and rolling out new technology platforms. Best-in-class B2B buyers invested in eProcurement integration and automation, enabling them to better adapt to a changing sales landscape. As a result, eProcurement has become the fastest-growing digital sales channel.

It is now more important than ever for suppliers to monitor and respond to procurement key performance indicators (KPIs). In a time where virtually every business is modernizing and undergoing rapid digital transformation, data is an anchor and a guide for businesses to make smarter, more informed decisions.

Supply chain disruptions will continue for the foreseeable future, and many businesses are using this opportunity to take a pulse check on their current procurement processes. They are re-evaluating the effectiveness of new systems, whether or not costs are under control, and if data entry and communication errors are disrupting supplier relationships.

As buyers complete their assessments, they are pinpointing the most important KPIs that drive the business forward, including:

- Contract Compliance Rates: Understand if suppliers fulfill your requirements

- Cost Per Invoice: Analyze the labor, overhead and software costs associated with purchase orders

- Spend Under Management: Track and optimize your spend

- Invoice/Purchase Order Accuracy: Measure the accuracy of procurement documents

- Procurement Cycle Time: Track how long the procurement process takes, from ordering to delivery and payment

- Number of Suppliers: Monitor the level of dependency towards suppliers

- Purchase Order Cycle Time: Know who to address your urgent orders to

- Supplier Availability: Measure your suppliers’ responses to urgencies

- Procurement Cost Reduction: Streamline the tangible costs savings

- Procurement Cost Avoidance: Avoid potential extra costs in the future

Identifying and understanding customers’ procurement key performance indicators is essential to helping suppliers better identify successes, supply risks and challenges.

What Are Procurement KPIs and Metrics?

Procurement leaders rely on data to gauge and report procurement performance. Setting goals and measuring against KPIs helps procurement teams understand the efficacy of current processes and areas of opportunity.

The distinction between metrics and KPIs is important. Metrics provide the raw data points, while KPIs are the specific goals organizations set based on those metrics. For example, “average cost per invoice” is a metric, but setting a goal to reduce that cost by 20% over the next year makes it a KPI. Together, they give procurement leaders actionable insights into efficiency, cost control, and supplier reliability.

It is critically important, however, that procurement KPIs are accurately measured and documented. Data hygiene is particularly important when assessing cost reduction opportunities, procurement ROI, spend under management, purchase order cycle time and more.

Why Procurement KPIs Matter for Suppliers

Suppliers that understand their buyers’ procurement KPIs gain a competitive edge. Buyers consistently evaluate performance to ensure suppliers:

- Deliver on-time and within agreed-upon terms

- Provide accurate invoices and purchase orders

- Offer competitive pricing with measurable cost savings

- Maintain availability of goods and services when needed

By aligning with these expectations, suppliers can improve buyer satisfaction, strengthen long-term relationships, and capture a larger share of spend.

TradeCentric’s eProcurement Integration can help you automate workflows, reduce costs, and stay aligned with buyer KPIs

10 Procurement KPIs Suppliers Can’t Afford to Ignore

1. Contract Compliance Rates

Compliance rates cover a variety of procurement KPIs, but they all seek to answer one overarching question: are suppliers complying with your business’s procurement policies and agreements?

Some questions a procurement department might ask are:

- Are suppliers delivering products within the contractually specified period?

- What proportion of invoices match agreed-on prices and discounts?

- How many invoices are disputed, and what is the difference between quoted prices and the final price the business pays?

- What proportion of delivered goods are defective or substandard?

Poor contractual and policy compliance rates indicate issues with supplier relationship management. They may reveal opportunities to improve cost savings by renegotiating contracts or moving to a supplier better aligned with the company’s expectations.

2. Cost Per Invoice

Cost per invoice, or CPI, is another important procurement KPI that measures the total procurement costs for each finalized invoice. This metric analyzes the labor, overhead and software costs associated with purchase orders, processing purchasing documents, and paying invoices. As a best practice, procurement operating expenses should be less than 1% of total spend, and CPI is a helpful way for procurement professionals to track whether they are processing invoices in the most cost effective way.

A good example of this is a procurement department that is transitioning from manual order processing to an automated and integrated eProcurement strategy that leverages solutions such as PunchOut catalogs, Purchase Order Automation, and electronic invoicing. Automation eliminates expensive manual processing, which in-turn greatly reduces time and resources spent finding and correcting errors. As a result, it is likely that CPI would be lower. The cost savings should continue as more supplier relationships are integrated into automated systems.

- Other similar procurement KPIs that focus on cost savings include annual cost savings, procurement ROI, and emergency purchase ratio.

3. Spend Under Management

Spend under management is the proportion of total spend managed by a procurement team. In organizations that use eProcurement software, it can be more narrowly defined as purchases conducted via the eProcurement system in line with procurement management department policies. Certain categories of spend, such as rogue spending, emergency purchases (and emergency purchase ratio) and other unmanaged spend rarely take advantage of negotiated discounts and other favorable contractual agreements. As such, these purchases inflate procurement costs and impact spend under management.

Cost avoidance, which is an active measure to reduce price increases in the procurement process, is a procurement metric that is often associated with spend under management. Unlike cost reduction, which looks to lower costs, cost avoidance is more likely to be impacted by supply chain disruptions and requires a unique procurement strategy.

- Other key performance indicators that work to improve cost avoidance include the procure to pay cycle, maverick spend, and overall procurement cost avoidance.

4. Invoice/Purchase Order Accuracy

Inaccurate procurement documents—including purchase orders, contract management and invoices—inflate operating costs and damage supplier relationships. They cause delays and increase processing costs during the procurement process. At their worst, they damage relationships to the point of legal action.

Human error is the primary cause of low purchase order accuracy, particularly due to manual processing and data entry. Organizations that adopt automated PO delivery and eInvoicing experience substantially improved accuracy, cost reduction and overall procurement performance.

5. Procurement Cycle Time

Procurement cycle time measures how long the procurement process takes, from ordering to delivery and payment. In the list of procurement KPIs, this is a helpful indicator of process efficiency and procurement ROI. Shorter cycle times result in greater agility, optimal stock levels and early payment discounts. Procurement cycle time is another example of a procurement KPI that can be beneficially affected by automation as manual processes often introduce unnecessary delays that can eat into cost savings.

6. Number of Suppliers

This KPI measures the company’s supplier count over time. Having too few suppliers poses a risk of dependency, while too many can limit discounts.

The KPI categorizes suppliers as contracted or unlisted. Contracted partners adhere to compliance terms, while unlisted ones do not. Contracted partners are further classified based on criteria such as discount rates and reliability.

7. Purchase Order Cycle Time

The purchase order cycle time tracks the entire ordering process, from purchase order creation to approval, receipt, invoice, and payment. It specifically focuses on the order process and excludes product creation and delivery.

8. Supplier Availability

Supplier availability measures how often goods are in stock or how many orders are fulfilled by the supplier. In today’s dynamic retail landscape, where consumer habits rapidly evolve and various sales channels converge, efficient supplier management ensures stock availability. Tracking supplier stock availability helps gauge their reliability over time.

9. Procurement Cost Reduction

Cost reduction is a primary focus within this list of procurement KPIs. It aims to quantify the tangible “hard savings” achieved through cost management efforts over time. These savings are easily measurable by comparing previous costs to current ones for the same goods or services.

Implementing best practices such as:

- Optimizing supplier lifecycle management,

- Utilizing supply chain analytics to enhance efficiency, and

- Providing staff training on cost-saving techniques are effective strategies for reducing expenses.

This metric holds significant importance for top management as it directly impacts the income statement.

10. Procurement Cost Avoidance

Our last procurement metric centers on preemptive measures taken to mitigate potential future expenses, such as preemptively replacing parts before they fail and cause further damage. These actions, often termed “soft savings” in contrast to tangible “hard” savings, may not be directly quantifiable on the bottom line but still yield positive impacts.

While sometimes overlooked by top management due to its indirect influence on the income statement, cost avoidance holds strategic significance as it typically targets strategic expenditures like new investments or innovative technologies without comparable alternatives.

Other Important Procurement KPIs to Consider

- Soft savings and other cost saving KPIs

- Future costs

- Price paid

- Overall cost

- Supplier defect rate

- Other manageable and actionable metrics

Tracking Procurement KPIs

The above ten procurement KPIs can give the business and stakeholders a temperature feel for how efficiently eProcurement solutions are working. Gathering the metrics for internal analysis and KPIs can be challenging and costly when procurement data and documents are hidden in fragmented systems.

Data transparency is one of the most significant benefits of integrating eProcurement solutions with supplier eCommerce stores via B2B connected commerce. Suppliers must understand that when their customers are evaluating the company’s operating costs and opportunities to reduce future costs, they will likely consider their supplier availability and ability to integrate with eProcurement solutions and how that may impact cost savings and procurement performance.

To maintain competitive advantage and earn or keep preferred supplier status, suppliers must understand their customers’ procurement metrics and how the procurement function measures success. Suppliers that are in tune with these KPIs will be better able to meet their buyers’ purchasing requirements and capture a higher percentage of wallet share.

Boost Procurement KPIs With TradeCentric

Buyers can enhance cost management techniques as well as enable procurement managers and teams by controlling procurement key performance indicators and finding an integrated and experienced B2B connected commerce business partner.

To learn more about how eProcurement integration and automation can help your business streamline the procurement process and gain insights into key procurement KPIs, contact us.

Procurement KPIs Frequently Asked Questions

Everything you need to know about our products and packages.

Procurement performance metrics are measurable values that track procurement efficiency, cost savings, and supplier effectiveness. They help buyers evaluate supplier performance and overall procurement success.

Commonly tracked procurement KPIs include contract compliance rates, cost per invoice, spend under management, cycle times, supplier availability, and cost reduction.

Suppliers that align with buyer KPIs strengthen relationships, capture more spend, and increase their chances of becoming preferred partners.

Metrics are raw data points, such as the average invoice cost. KPIs are goals set using those metrics, such as reducing invoice costs by 20% in a year.

eProcurement solutions, including PunchOut, PO automation, and invoice automation, reduce errors, shorten cycle times, and provide visibility into procurement data. This helps both buyers and suppliers achieve stronger KPI outcomes.